- Unique structural design to give a rigid and stable structure.

- Chemically treated Pine wood for durability.

- Optimal selection of tower configuration, Splash bar and PVC drift eliminators

- Efficient & Enery saving fans and mechanical equipment.

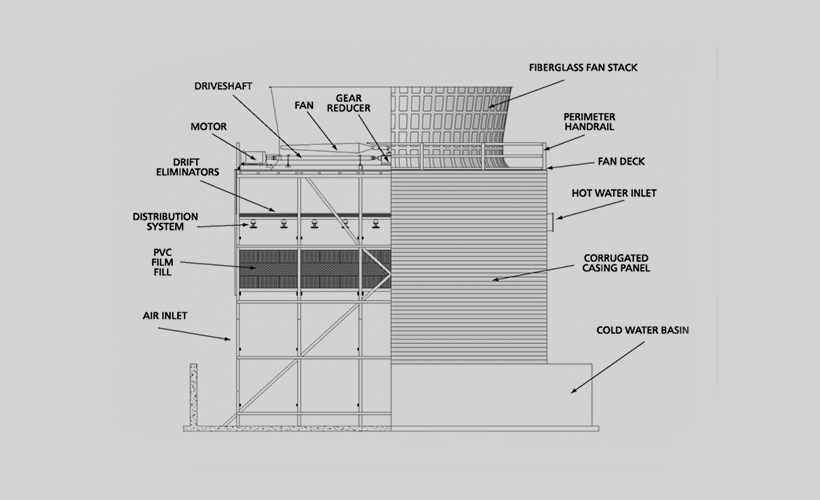

Induced Draft Counter Flow

In a counter flow cooling tower the air moves vertically upwards through the fill while water falls vertically downwards. Film type fill is used and is suitable for all cooling load applications. The structure of the cooling towers are made of Treated Pine wood. Film type fill is made of PVC for normal water applications. These cooling towers are fitted with the fills of wider flute so that it can withstand most of the industrial water. In the case of contaminated water PVC ‘V’ bars and grid can be used. Cooling towers are fitted with high efficiency machines such as exhuast fans, gear boxes and drive shafts.

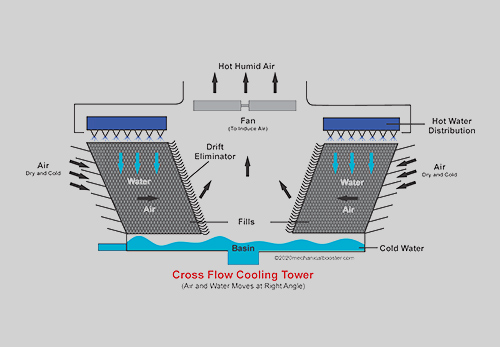

Induced Draft Cross Flow

In a cross-flow cooling tower air moves through the fill horizontally and water falls vertically. The fill used is splash type fill and is suitable for cooling all load applications. It is more suitable for the application where water has higher suspended solids which can be a problem for film fill cooling tower operation. For high temperature applications the splash fill is made of chemically treated Pine wood whereas for normal temperature applications it is made of PVC. It can be of rectangular or ‘V’ bar shape. The fill is supported on a SS grid. Cooling towers are fitted with high efficiency mechanical parts such as exhaust fans, gear boxes and drive shafts.